Latin America is rich in opportunities, from growing market reach to rationalizing operating costs, but it is a region that also presents challenges.

For nearly two decades, we have been working in Latin America in a variety of consulting roles and, more often than not, we see our clients consistently facing one or more of the following issues:

- Managing Complexity

- Understanding Cost to Serve

- Improving Working Capital

- Optimizing Back Office Operations

- Leveraging Technology

We started a series of blog posts to share some of our views and lessons learned on these topics. The first one, Five Pressing Issues Confronting Multinationals in Latin America, provides an overview and sets up the discussion context. In this post, we will delve into improving Working Capital.

While everyone recognizes the importance of working capital, its components are often managed in isolation. Companies operating in Latin America tend to overly extend the cash conversion cycle due to a number of factors, including deficient collection policies, poor sales projections and complexities associated with inventory management.

The heterogeneity of the region adds complexity to inventory planning and often results in lack of accountability, low policy compliance and poor decision-making. Enhancing visibility across the supply chain and establishing the right accountabilities, inventory policies and priorities are also keys to maintain service levels while keeping inventory levels from skyrocketing and ensuring profitability.

Where Do You Start?

To ensure success and profitability, it is essential for any business selling goods to have the right inventory available where and when it is needed.

Inventory is an investment that, if managed well, can bring maximum benefit. Requisite to proper inventory management is complete knowledge of your inventory. This means having visibility over your current inventory from source to fulfilled order, as well as traceability of your historic inventory.

There are hundreds of software tools that companies can utilize to provide them with the total picture of the inventory throughout their supply chain. Your company probably already has licenses for several of these software tools. Getting the full benefit from any of these tools to help optimize the inventory management process is one of the main challenges. However, software is only effective when the right policies, processes, controls and practices are in place to ensure that stock levels are precisely where they need to be, when they need to be there to enable the accurate, complete fulfillment of every customer’s order.

Businesses must know what inventory is currently in stock, so as to not over-order products. Having too much inventory, or the wrong selection of inventory, means that a business’s precious cash is tied up in a low or no return venture, while better return opportunities go unfunded. Too much inventory can also result in product obsolescence or waste, especially if the stock is perishable. Obviously, items such as fresh produce have extremely short shelf lives and spoil if stockpiled. Other items may not be “perishable.” but still may have short “shelf life,” such as trendy teen accessories or electronic devices utilizing yesterday’s technology that can obsolesce quickly and often take up an inordinate amount of space in warehouses.

Overstocked items also consume space, which costs money, especially if the company uses multiple locations to serve one geographic market or is paying a third party to store overflow. Excess inventory can cost in terms of productivity, when storage utilization exceeds the point at which inventory can be optimally slotted to minimize material handling vehicle travel and operator labor cost.

What’s Needed?

It is the combination of the right tools providing clear visibility of demand and inventory, measurable processes, and the operational flexibility to respond efficiently to feedback that enables the proper management of inventory and eliminates overstocks.

The real benefit of using the right combination of tools is the ability to convert unnecessary inventory into cash for high ROI investments. For example, a home appliances distributor that uses several “off-site” warehouses in addition to its three distribution centers recently determined that if it were to divest itself of the inventory in two of its auxiliary warehouses with dismally low inventory turns, the company would no longer incur well over one million dollars annually in operating costs and would be able to reinvest those dollars tied up in inventory more profitably. If this distributor redirected this inventory investment and earned a mere 8% APR, that would provide them $1.6 million annually. As most companies, this distributor has many proposed projects vying for funding, which the combined savings and earnings of $2.6 million could support. The motivation to divest itself of excess inventory came from the discovery of the value of converting that inventory quickly.

Some businesses also have under-stocked inventory items, and unfortunately, in more cases than not, these are the same businesses that have overstocked many items. There is a common thread here: the lack of adequate inventory management strategy and tactics. The reality is that most businesses ignore many inventory problems, especially if they are not glaringly obvious. If business is good and/or the distribution center personnel don’t complain about inhaling dust from old inventory (and they receive overtime pay to cross-dock items for a shipment), these issues tend to get “swept under the rug.”

Who can even calculate the lost sales resulting from orders shipped incomplete? “Back orders” leave a negative impression of the seller/shipper, even if they are shipped within minutes of the rest of the original order’s shipment. And this sentiment doesn’t even compare with that of irate customers who are promised merchandise by an advertisement, only to learn that the promotional item is not theirs to take home.

To compound the issue, inventory management is often a political “hot potato.” Sales pushes to have all products available for shipment at any time, prompting Procurement to fill the warehouse with inventory just in case customer demand exceeds expectations, while Customer Service pushes to have orders shipped immediately. The Warehouse attempts to efficiently store product and fulfill orders despite being crowded by stagnant inventory, and Finance tries to control costs. The results are often based on reaction to the latest events, rather than on effective policies and sound business decisions.

So how does a company go about paying enough attention to its inventory in order to receive the highest payoff? It takes an objective view, along with the knowledge and experience about “what works” in your business, to first identify the type of inventory issues that exist, their impact and root causes, as well as what do to about them. To be totally informed and in control, profit-wise, over your inventory decision-making processes, a number of key business processes need to be assessed.

How Do You Rate?

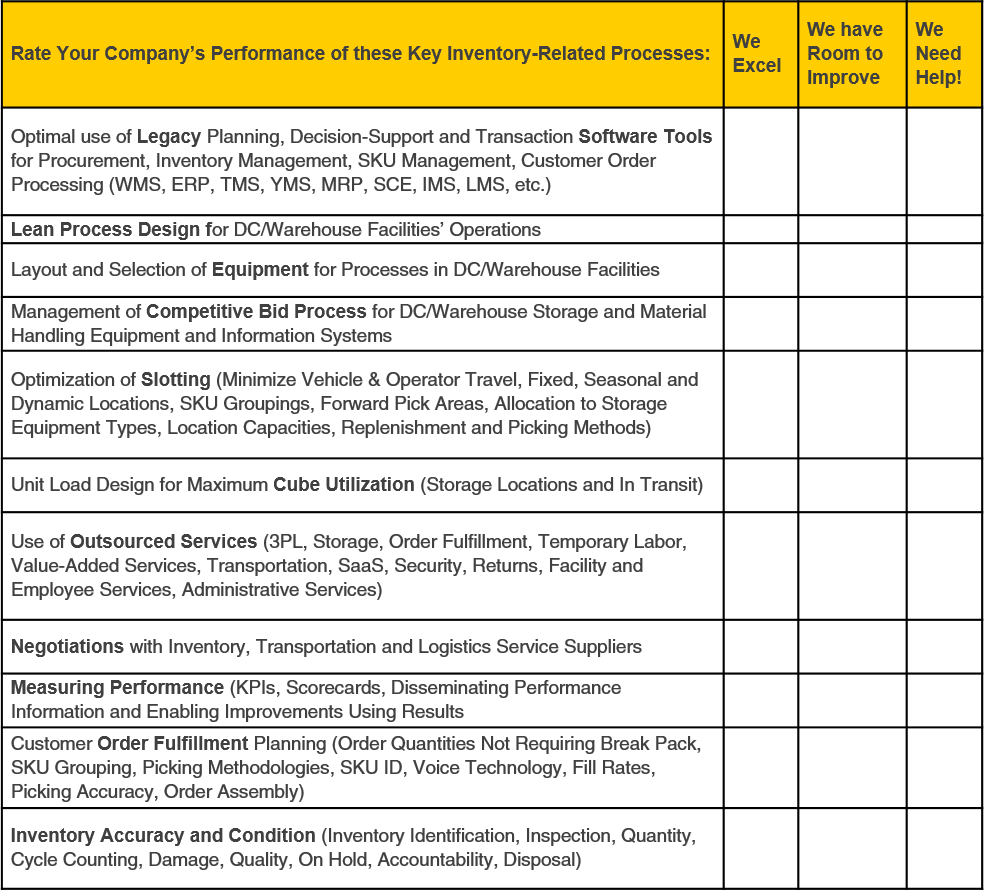

All of the elements in the checklist in the proceeding section affect inventory and your company’s ability to convert it to profits.

Take a moment to rate how well your organization performs these inventory-related processes. Does your company follow industry best practices, make full use of its information systems and supply chain assets, and regularly evaluate the potential of applying the latest technologies to your business? This checklist can be used to pinpoint your company’s opportunities to improve the way it moves inventory to make money.

The primary components of inventory management, planning and optimization are key to ensuring that the right products, in the right amount, get to the right place at the right time. This is a juggling act that sounds simple, but involves the effective coordination of a lot of “moving parts.” Miss on one, and the impact can be significant, including lost margin, poor customer relations and lost sales. And the situation can be even more dire if the “moving parts” stop moving, indicating that your inventory investment portfolio needs better portfolio management.

Make it Happen

Managing inventory in Latin America is one of today’s top challenges for multinationals. We hope these ideas help spark some action as you rethink your approach for doing business in the region. The great news is that with the proper tools and inventory decision-making processes in place, future inventory decisions can be made with much more assurance that your inventory’s sojourn through your business’s supply chain will be minimized and will effectively enhance your company’s bottom line.

How are you managing inventory in Latin America today?